Dongtai Dongya light industry machinery Co., Ltd. belong to the Group of Dongtai foodstuffs machinery factory Co., Ltd. which is specialized in drum dryer and peripheral products development and manufacture company, is China's leading science and technology enterprises. We are focus in Drum dryer applications in industry has accumulated over thirty years of experience. Using the principle of drum dryer, around its drying characteristics, successfully applied to the petrochemical, food ingredients, brewer's yeast, sewage treatment, construction material, and many other fields. The market is based in China and also on expanding overseas markets. Various drum dryer total yield more than 1,000 units were sold in all over the world, ranking first in the world, the products have been exported to 28 countries and regions worldwide including USA, Canada, Japan, Europe. With our technical service to your business, to join hands in creating a better future.

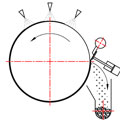

Drum dryer is a kind of the drying processing. Generally, the drying is used to obtain dried material from the slurry. The machine has been widely used in many industries, such as the pharmaceutical industry, chemical industry, food industry, sewage treatment and other industries. Drying process in general, is to a certain concentration of the material delivered to the surface of the rotary heat drum, rotation of the drum is inside pass by high-pressure steam to maintain a higher temperature. Material stuck to the surface of the drum, and the drum is rotated when it in process, the water of the material in the film due to the effect of high temperature quickly evaporates. When the film dried on a steady stream of running time, dryed material will be easily scraped off by a blade continuously from the drum surface into the chute. Then the material will be grinded by pulverizer according to the end user's demand to different size, then products packaging.

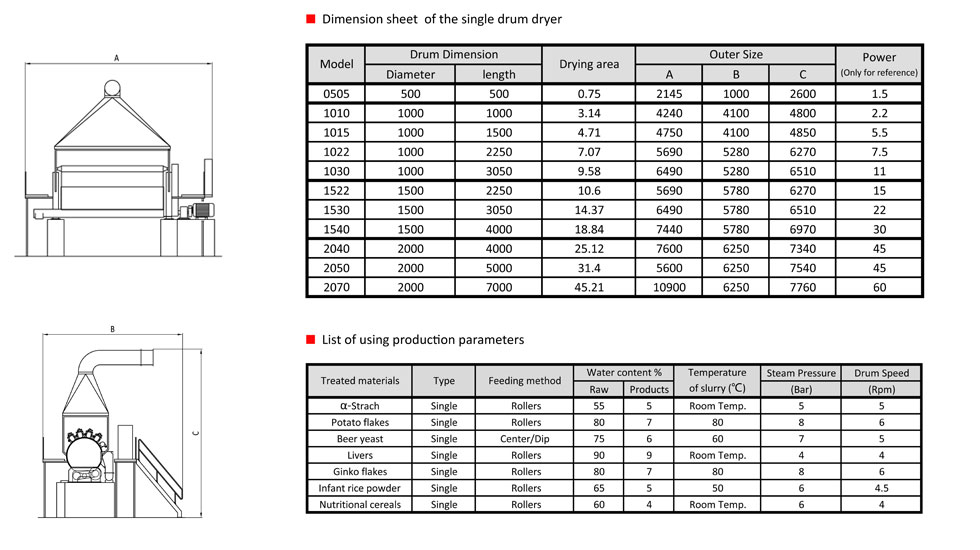

This type of device contains only one main drum. When working, the drum heated with steam by the inside and the drum rotate, in the rotation process will keep the interior of the condensate discharge. And the heat will reach dynamic equilibrium. Mainly in the form of single drum distinction feeding ground of the layout, a different cloth division applied to different areas of work. Select the appropriate forms depending on the material properties of the material.

Double drum dryer have two main drums, which are heated with steam by the inside and rotate, and the slurry was feed into the gap between two drums. And there are two baffles against the end of the drum, the baffles are prevent the slurry get out of the feeding area. The drum rotate in different direction. It is used to dry the material of medium viscosity. The final film normally is thin than the single drum dryer. According to the different material, there are four kind of structure.

The machine is used to dry the Paste of medium-highviscosity and high consistency. It can form equal film under the function of little rollers grinding. That availably prevents the sticky paste form the mass. the amount of the little rollers is between 2 and 7, it can fit the wide application of different materials and finished products.

It is used to dry the hot sensitive matter of low viscosity and consistency. it is mainly used to dry yeast, feed, pigment, all kinkd of chemical industry material, environmental protection products.Etc.

It is used to dry used the hot sensitive materials of medium consistencz and low viscosity.It is mainly used to dry concentrated juice of fruit and vegetable,eggs and china herbal medicine.

The machine is used dry the materials of medium viscosity such as α-starch, glue, whey, milk powder, dehydrated yeast mud, fish and shrimp feed, high consistency pigment and environmentalprotection product, it is high efficiency, good physical quality and low shearing force.

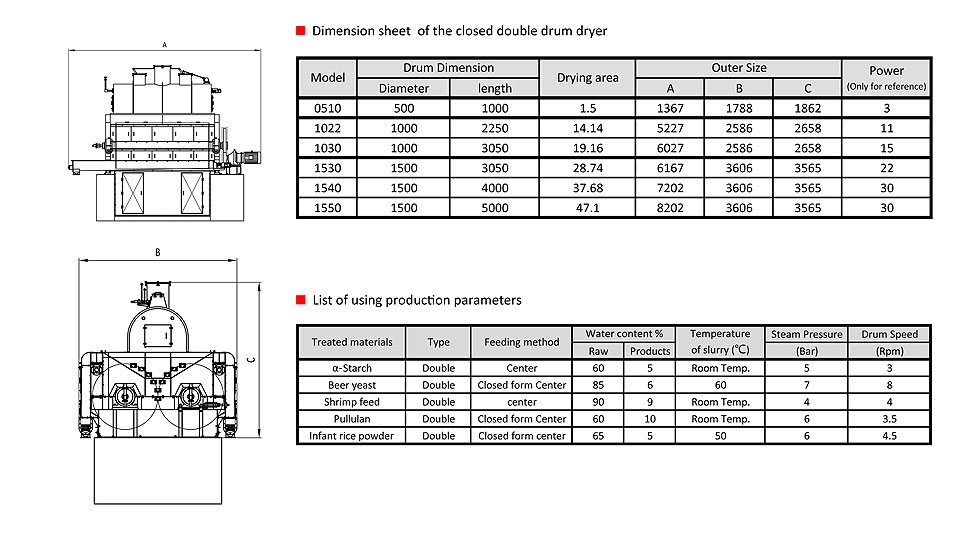

The structural optimization based on the type of the meshing structure, wet and dry part is separated, and designed two baffles against the end of the drum, in order to achieve the effect of pre-boiled slurry. The environment of working relative isolation, health conditions. When the device running, inside which is micro negative pressure. Suitable for processing low viscosity materials such as: yeast, infant nutrition rice cereal.

The machine is used dry several kinds of material. It is a combination of single and double roller. The finished products are good quality, nice colour. It is thinkness can be adjusted easily.

The machine is used dry the liquid of low viscosity and high humidity. It is mainly used in chemical industry and environmental protection industry.

Our products are used in different production lines, rice flour machine,

cereal production line, potato deep processing